Cartridge seals are by far the easiest seal to install. It requires sliding the gland over the shaft, tightening the gland bolts, using an allen wrench to tighten the set screws to the pump shaft, and removing the setting clips. The purpose of the setting clips is make sure the seal faces are locked into position on the shaft that provides enough force to maintain a seal, but not too much force that would cause premature wear. The cartridge seal cannot be miss installed. 50% of seal failures are caused by Cartridge seals are by far the easiest seal to install. It requires sliding the gland over the shaft, tightening the gland bolts, using an allen wrench to tighten the set screws to the pump shaft, and removing the setting clips. The purpose of the setting clips is make sure the seal faces are locked into position on the shaft that provides enough force to maintain a seal, but not too much force that would cause premature wear. The cartridge seal cannot be miss installed. 50% of seal failures are caused by miss-installation. Cartridge seals nearly eliminate miss-installation (cartridge seals can still be dropped while being installed, causing failure).

Cartridge seals must fit the stuffing box there is a form

Seal Application Data Form to help the make sure the mechanical cartridge seal fits the pump. You can also order our cartridge seals on line.

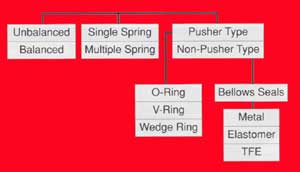

Installation of other seal types such as single spring, multiple spring seals, and metal bellows require a careful calculation to assure the seal is placed in the correct position on the shaft. Over compression of the seal will prematurely wear it, while under compression can permit leakage or not seal at all. When installed properly, in the right application, seals often run for as long as 20 years. Mechanical seal life spans will vary greatly depending on the application. Fo help, ask your American Seal & Packing sales representative for installation directions.